Bio-Sal™ Technology

NanoWater is an engineering Company provides

complete water and wastewater solutions and services

using cutting-edge technologies to serve municipal and industrial clients. NanoWater has the in-house capabilities

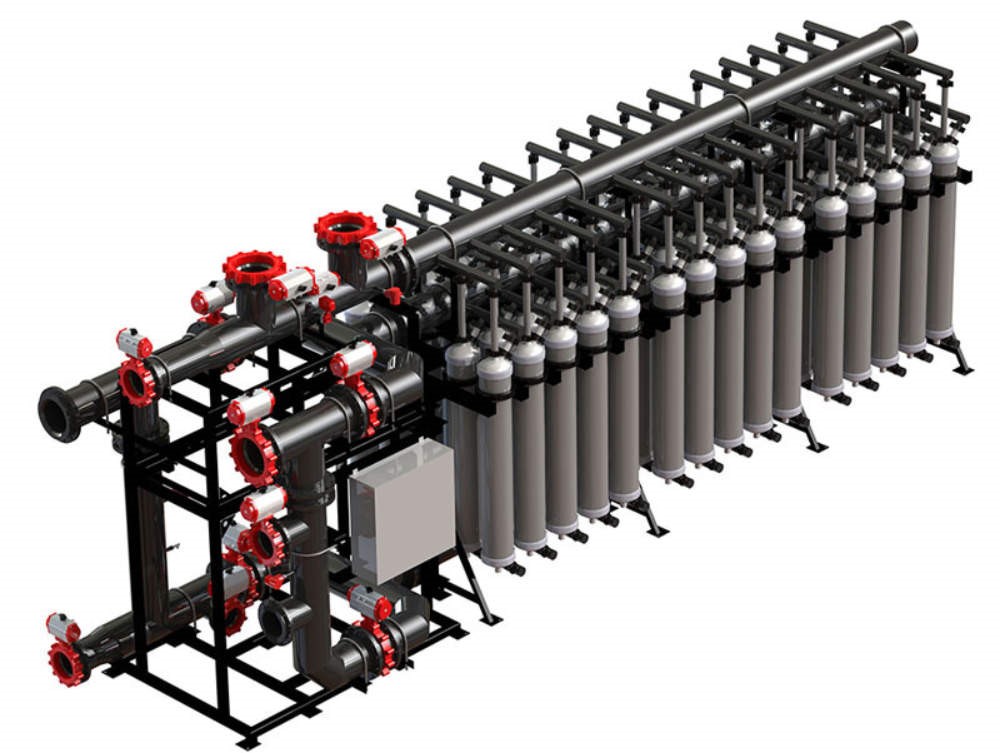

in design, engineering and manufacturing. NanoWater manufactures water filtration systems for all applications where reverse osmosis (RO), seawater desalination (SWRO) & brackish reverse osmosis (BWRO ) , ultrafiltration (UF) and other membrane water treatment technologies are proven.

Our Water Experts and Engineers can create custom solutions to solve virtually any water treatment challenge. From feed water report analysis, detailed drawing and budgetary proposals, prototype and pilot testing, to system startup, our technicians are involved every step of the way

to ensure the success of the project. With thousands of installations in operation world-wide, NanoWater solutions

have a long history of serving a wide range of markets.

Energy Saving SWRO Projects

NanoWater team has more than 100 years of a combined experience in the desalination industries. We understand how the desalination plant works and where are the weaknesses in operation which usually leads to a high power consumptions and reduces the plant efficiency. During the last 10 years our engineers have been focusing on finding solutions to the root cause of the SWRO projects operational deficiencies and had developed solutions which not only reduce the plant power consumptions but also offers a sustainable operation of the projects .Our Engineers also have developed a process design to increase the brackish water RO recovery to exceed 95% in lieu to the conventional design which offers only 65% or less in recovery.

Sustainability & Project Life Cycle Cost (LCC)

The life-cycle cost of a plant is one of the most important factors when planning and specifying equipment. Over the 20–25 year life of a large SWRO facility, the operating cost will tend to outweigh the initial capital investment. The largest component of the operational expense is the cost of power. The RO process which includes the high-pressure pumping equipment can consume over 20% of the entire plant power and in some cases up to 45%. The required power is a direct result of the efficiency of equipment. High-efficiency centrifugal pumps as well as both isobaric and centrifugal ERDs have become common place to help reduce power consumption, greenhouse gas emissions, etc

RO PRETREATMENT

Ultra Filtration

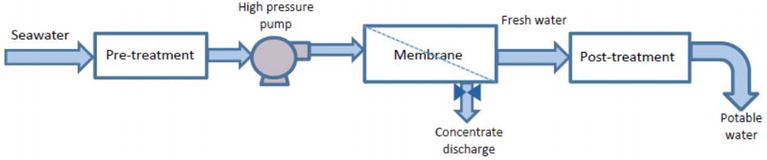

Seawater pre-treatment is an integral part of every seawater reverse osmosis (SWRO) desalination plant. Ideally, after pre-treatment the only solids left in the seawater would be the dissolved minerals and as long as the seawater system is operated in a manner that prevents minerals from precipitating on the membrane surface, the SWRO membranes could operate without any cleaning for a very long time.

pre-treatment systems remove most but not all of the suspended solids contained in the source seawater and so are prone to fouling by the suspended solids, particulates and silt that remain in the seawater after pre-treatment. Fouling can be reverted by periodic cleaning of the SWRO, however in some cases, membrane fouling could be irreversible and cleaning may not recover productivity, which may require the replacement of some or all of the SWRO membranes.

Filter Media

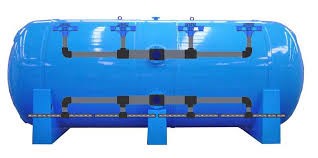

Vertical Pressure Multimedia Filter

Custom Engineered Seawater Desalination SWRO Systems

NanoWater experience extends beyond standard seawater desalination systems. We have supplied complete seawater desalination SWRO systems

with Energy Recovery, Data Logging, Scada system , Containerized Systems, Explosion Proof Systems, Portable Systems , and many more up to millions of gallons per day

HORIZANTAL MULTI MEDIA FILTER

Post Treatment

Post-treatment processes typically include stabilization, disinfection and corrosion control, and can include degasification and/or air stripping processes. Four primary issues concerning the post-treatment water are blending, remineralization, disinfection and the materials used for storage.

Reverse osmosis (RO) permeate is aggressive, corrosive since it is soft, low alkalinity water with slightly acidic pH. Unless properly post-treated, finished water from RO facilities can cause corrosion to downstream fixtures and piping including the distribution system. Post-treatment includes chemical addition to adjust water quality. Blending a controlled amount of raw water with permeate before disinfection and distribution is typically applied when water quality allows to lower, or in some cases eliminate, consumption of corrosion control chemicals

Post-Treatment Processes Seawater RO

The remineralization steps result in raising pH, alkalinity, and hardness of the water, thereby stabilizing the water. For the permeate from the RO trains, hydrated lime and sodium hypochlorite are added.

Limestone contactors are used to neutralize the pH and to add calcium and bicarbonates of corrosive waters such as Reverse Osmosis permeate. Biotech design equipment of different sizes to suit varied client installations, from small units for hotels and factories, to large plants for towns and cities.

- Recarbonation.

- Lime addition.

- Calcite bed filtration.

- pH and/or alkalinity adjustment.

- Addition of corrosion inhibitors.

- Primary and secondary disinfection.

- Blending with fresh water supplies

Bio-Sal™ Technology

Reverse Osmosis desalination suffer from high biological fouling which leads to following

- Lack of the permeate flow

- Increase the pressure differential across the membranes

- Increase in the energy consumption

- intensive chemical treatments which leads to the membranes damages.

Existing solutions, directed to killing and eradicating microbes, are suboptimal and harmful, as they are either chemical intensive, inefficient or both.

Bio-Sal™ Technology

NanoWater utilizing a Peptide-based coatings and solutions (Bio-Pep™) in a very low concentration as (ppb )

- Cleaning solution

- Additive as biocides / antibiotics enhancer

Our peptide been classified by the US-EPA as Low-risk Antibacterial Material (Biochemical pesticide) and approved by the main RO membranes manufacturers.

Bio-Sal™ is a low energy consumption and green technology developed by Biotech Technologies engineers and researchers for the Reverse Osmosis industry

The advantages of the Bio-Sal™ Technology are

- Minimize the biofouling effects

- Decrease the cleaning frequency

- Keep the Pressure differential stable

- Decrease the chemical usage

- Increase the system recovery

- Increase the system availability

- Decrease the energy consumption.

NanoWater specializes in tailored water treatment solutions to meet the specific needs of our clients. We support municipal and industrial projects, remediation, food and beverage, water reuse, agriculture, power & utilities, breweries, mining, oil & gas, hotels and resorts as well as pharmaceutical industry.

From conceptual design to technical O&M support, NanoWater extensive experience offers value to our customers. NanoWater commitment to innovation and applications of advanced technologies as well as the quality of execution.