Desalination Technologies

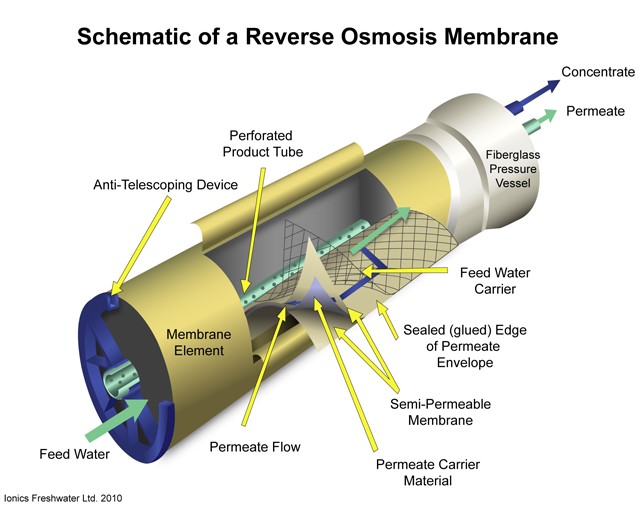

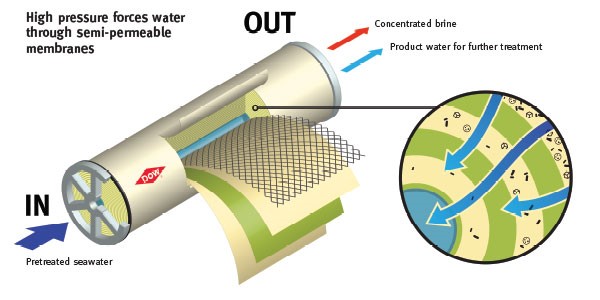

Desalination is any process that removes excess salts and other minerals from water. In most desalination processes, feed water is treated and two streams of water are produced:

- Treated fresh water that has low concentrations of salts and minerals

- Concentrate or brine, which has salt and mineral concentrations higher than that of the feed water

The feed water for desalination processes can be seawater or brackish water. Brackish water contains more salt than does fresh water and less than salt water.

The most widely applied and commercially available technologies for sea water desalination can be divided in two types: membrane processes and thermal processes.

The advances in key equipment (membranes, pumps, energy cost recovery device), turned the process energy efficient, resulting in a low investment cost (CAPEX) and low operational cost (OPEX).

- The pretreatment: includes all the necessary treatment step ahead of the reverse osmosis plant. It is determining for plant life time and to minimize chemical cleaning and membrane replacement. It has a direct impact on the plant performance.

- The reverse osmosis process: can also be built with one or two passes, depending on the product water requirements and the seawater salinity and temperature. In most cases, 1 pass is sufficient to rich the EU drinking water standards, especially regarding the boron content (1 mg/L). WHO boron guideline (2 mg/L).

Additional RO configurations involve passing RO concentrate through a second RO unit have been designed to achieve increased recovery and reduced concentrate volume, reducing plant size requirements. However, SEC is increased due to high pressure requirements of the second pass.

Energy savings can also be gained by grouping the RO plant components into three banks (high pressure feed; membrane; energy recovery), referred to as “three center RO.” This configuration has been adopted in large RO plants in Australia, Israel and Middle East and provides reduced energy demand for diurnal flows . However, three center design will not provide benefit where SWRO supplies only a small portion of total demand and therefore required to operate in batch mode (constant flow), as is the case for desalination plants utilized to supplement existing freshwater supplies.

SPSP is the preferred configuration where product quality requirements are higher, demanding second pass RO. Further investigation is required to verify the comparative benefits of three center RO

- The Energy Recovery: The Energy recovery device is the key factor that determines the plant electrical costs. It must be chosen carefully based on the local energy costs and environment policies.

Post-treatment

and/or polishing steps are required to condition the water after the reverse osmosis membrane process to make it suitable to the intended application. The WHO recommends 10 mg/L of Magnesium and 30 mg/L of Calcium for drinking water.

Process No. 1

CO2 addition + Calcite Limestone (CaCO3, MgO) percolation + Na2CO3

80 mg/L CaCO3

pH 7-7.5

Process No. 2

Addition of CaCl2 + NaHCO3

Pressure Exchanger® (PX) family of products provides unmatched energy recovery for seawater reverse osmosis (SWRO) desalination systems. Large and small desalination projects around the world rely on our range of PXs to achieve optimal operations and maximum energy savings. Designed with only one moving part using highly engineered alumina ceramic, the PX stands up to the harshest of environments resulting in an unmatched life cycle cost advantage.

RO Process Configurations

Several process configurations of SWRO have been developed to achieve improvements in both energy efficiency and water quality.

- Single pass RO is the conventional and most widely adopted configuration due to its simplicity, ease of operation, and comparatively low cost. Single pass RO produces permeate with a TDS (total dissolved solids) concentration between 300 and 500 mg L−1 and has a recovery rate of up to 50% . Where higher quality product water is required, additional RO pass may be required.

- Two pass RO involves a second RO unit in series which further treats permeate from the first to achieve improved quality. The additional energy (and cost) required to run the second RO makes this option generally unfeasible.

- Partial two pass RO involves feeding a portion of the first pass permeate through the second RO, while the remaining permeate bypasses the RO, blending with the second pass permeate. The SEC is dependent on the ratio of permeate treated to permeate bypassed

- Split partial RO configurations involve the extraction of permeate from different points along the membrane module. The front (upstream) elements produce higher quality permeate than rear (downstream) elements. Split partial RO therefore takes advantage of the lower salinity front permeate by directing it straight to the product stream, while the higher salinity rear permeate is treated further, either by diluting with seawater feed and recycling back through the RO unit (split partial single pass, SSP, or passing through a second RO system (split partial second pass, SPSP.

SSP has been reported to reduce fouling and increase SWRO operation as well as decrease energy consumption and improve permeate quality by up to 15% compared with conventional single pass . With SPSP, the front permeate (lower TDS) bypasses the second-pass RO, while the rear permeate is fed into the second-pass, after which the two permeates are mixed. SPSP is reported to have the lowest SEC of the two pass configurations

100 mg/L CaCO3

100 mg/L Na + 50 mg/L Cl

pH 7-7.5

- Brine disposal can be an environmental and economical issue in some areas where the fauna and flora are sensitive to local seawater salinity increase. Brine disposal should be studied and engineered case by case pls consult Nanwater for further detail at sales@nanowaterusa.com

A Leading Desalination Provider

NanoWater is the first choice for businesses considering the desalination Industry. We specialize in delivering SWRO & BWRO systems using the latest technology and expertise. NanoWater continuously innovates and develops new products and services that purify water and protect against contaminants, allowing businesses to perform as designed. Our team of experienced engineers and project managers ensure we provide a system that is exactly suited to your requirements. You can be assured that our systems use the latest technology on the market Contact us today at sales@nanowaterusa.com for more information on how we can help you.