INDUSTRIAL WASTEWATER TREATMENT TECHNOLOGIES

Industrial wastewater is a major challenge in processing industries, it usually contains a range of organic and inorganic matters in varying concentrations. Many materials are toxic, mutagenic, carcinogenic or almost nonbiodegradable. This means that the wastewater also contains a range of substances that cannot be easily degraded. Industrial waste water contains high levels of chemicals, effluents, and toxins which are extremely harmful to human being and environment. Given its hazardous content, industrial waste water requires to remove the Oil, Suspended Solid (SS), COD, BOD, T-P, T-N, pH etc. in order to reuse and/or meet the discharge limits of the required water quality. Pre-treatment facilities technology such as API/ CPI/ DAF (IAF) separators in specialty increases operating efficiencies of the post-treatment facilities by reducing the influent oil and suspended solids.

Industrial Waste Primary treatment

Primary treatment involves the removal of solids, particles and oils in the industrial wastewater stream; therefore, primary treatment usually contains basic physical methods and solid/oil separations such as primary clarifiers, oil separators and screens.

Industrial Waste Secondary treatment

Secondary treatment is usually the heart of the treatment unit where suspended and residual organics and compounds are broken down. Secondary treatment usually involves biological (bacterial) degradation of contaminations and pollutants. Aerated activated sludge treatment has been known as one of the best solutions for secondary treatment. It is simple, cost-effective and high-performing.

NanoWater Solutions

NanoWater design a Combinations of anaerobic and aerobic treatment processes which is an efficient way in the removal of many pollutants such as soluble biodegradable organic pollutants. Chemical oxidation techniques to treat wastewater are also on the rise because of tighter treated wastewater limits. NanoWater designs both classical chemical treatment and advanced oxidation processes have been used in modern industrial wastewater units. NanoWater usually utilizes a combination of technologies in industrial wastewater treatment, including physicochemical, biological and advanced oxidation processes, used in processing industries.

Oil removal ( CPI / TPI / DAF / NSF / IGF)

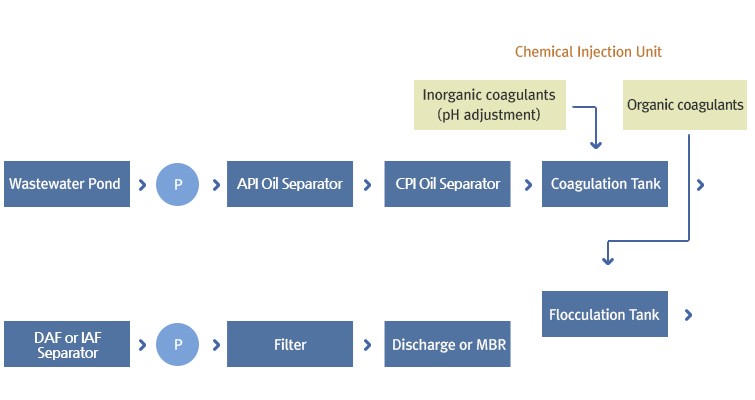

Oily wastewater have included gravity separation and skimming, dissolved air flotation (Nano-DAF™), de-emulsification, coagulation and flocculation. Gravity separation followed by skimming is effective in removing free oil from industrial wastewater.

The API oil-water separator is designed to separate the oil and suspended solids from wastewater. An API separator or other basic oil-water separator, however, is not effective in removing smaller oil droplets and emulsions. Oil that adheres to the surface of solid particles can be effectively removed by sedimentation in a primary clarifier.

NanoDAF™ is one of the most effective methods to treat small oil droplets and emulsions. DAF uses air to increase the buoyancy of small oil droplets and enhance separation. Emulsified oil in DAF is removed by de-emulsification with chemicals, thermal energy or both. DAF units typically employ chemicals to promote coagulation and increase flock size to facilitate separation.

Coagulation and flocculation

Most industrial wastewater treatment units include sedimentation in their processes. Sedimentation, also called clarification, is a treatment process in which the velocity of the wastewater is lowered below the suspension velocity, and the suspended particles settle out of the wastewater due to gravity. Settled solids are removed as sludge, and floating solids are removed as scum.

Biological treatment

Biological processes deal primarily with organic impurities. Microbial-based technologies have been used over the last century for the treatment of industrial wastewater. The development of these technologies has provided successful processes for the destruction of waste constituents readily biodegradable under aerobic conditions. Aerobic degradation in the presence of oxygen can be a relatively simple, inexpensive and environmentally friendly way to degrade wastes. Soluble organic sources of biochemical oxygen demand (BOD) can be removed by any viable microbial process — aerobic, anaerobic or anoxic. However, aerobic processes are typically used as the principal means of BOD reduction of wastewater because the aerobic microbial reactions are fast typically 10 times faster than anaerobic microbial reactions. Therefore, aerobic reactors can be built relatively small and open to the atmosphere, yielding the most economical means of BOD reduction.

Anaerobic reactors differ from aerobic reactors primarily because the former should be closed to exclude oxygen from the system to avoid interference with anaerobic metabolism.”

Activated sludge treatment methods have been widely used to treat industrial wastewater. New technologies of membrane bioreactors (MBR) that have been inoculated with activated sludge have shown to effectively treat high-strength organic wastewater. On the other hand, the two-phase partitioning reactor has also been effective with toxic substrates.

Anaerobic reactors differ from aerobic reactors primarily because the former should be closed to exclude oxygen from the system to avoid interference with anaerobic metabolism. An anaerobic reactor should be provided with an appropriate vent or a collection system to remove the gases (mainly methane and carbon dioxide) produced during anaerobiosis.

Advanced oxidation

Advanced oxidation processes (AOPs) constitute a promising technology for the treatment of wastewaters containing non-easily removable organic compounds. All AOP are designed to produce hydroxyl radicals. It is the hydroxyl radicals that act with high efficiency to destroy organic compounds. AOP combine ozone (BioZone™), ultraviolet (UVDOS™) , hydrogen peroxide (H2O2) and/or catalyst to offer a powerful water treatment solution for the reduction and/or removal of residual organic compounds as measured by COD, BOD or TOC.

Advantages of Advanced Oxidation Processes

- Rapid reaction rates.

- Small foot print.

- Potential to reduce toxicity and possibly complete mineralization of organics treated.

- Does not concentrate waste for further treatment with methods such as membranes.

- Does not produce materials that require further treatment such as “spent carbon” from activated carbon absorption.

- Does not create sludge as with physical chemical process or biological processes (wasted biological sludge).

Disadvantages of Advanced Oxidation Processes

- Capital Intensive.

- Complex chemistry must be tailored to specific application.

- For some applications quenching of excess peroxide is require.

NanoWater is one of the world’s leading companies in the Water and Wastewater treatment industry, NanoWater Design , Engineer , Procure ,installation , commissioning with Operation and Maintenance . Please feel free to contact to discuss your project at sales@nanowaterusa.com